-> Ucancam Knowledge Base

Ucancam Pro = Ucancam Standard Version + Waveboard + Surface\Relief ( CAD&CAM ) + Interactive Nesting. Ucancam Pro is a powerful, flexible industrial strength software. Ucancam Pro includes all the design, layout and machining functionality demanded by commercial shops and users, while remaining incredibly easy to use and affordably priced. Ucancam Pro is a complete solution for 3D Model Making (Surface, Relief, Canvas 3D, CNC routing,engraving,and milling ), Rapid Prototyping and Sign making, Wood Carving( Custom fireplaces, door panels), Stone cutting(Memorials, Commemorative plaques) . As well as the current mainstream Ucancam Pro’s 3D Wave board, for this, Pro. offers all the tools you need for surface waveboard designs’ machining, such existing wave-shaped designs as lines, curves, waves can be created on MDF boards. In addition, Original and unique designs and even users’special requirements for cutting characters or graphs on finished wave boards can also be grabed.Various artistic effects can be achieved through different treatment of MDF boards through Ucancam Pro.

|

File formats supported: import the Iges,Stl,Obj file | |

|

Standard surfaces creation Plane, sphere, cylinder, cone, ellipsoid, torus | |

|

Free surfaces creation Loft, rule, sweep along a path with edge matching, sweep along two rail curves with edge continuity, revolve,blend, patch. | |

|

|

Surfaces edit Chamfer, fillet, extend, trim, untrim, split surface by isoparam | |

|

|

Extrude surface | |

|

|

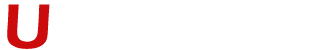

Variable radius Fillet/chamfer | |

|

|

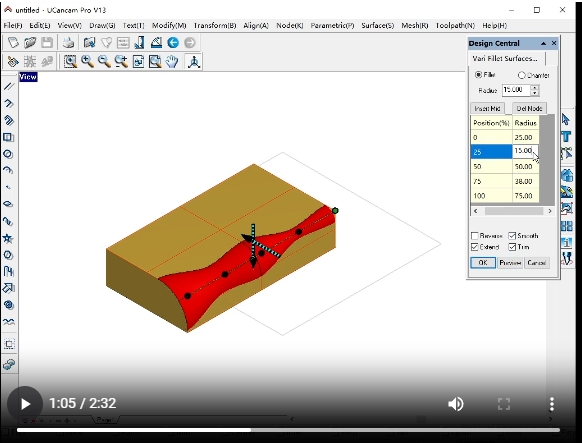

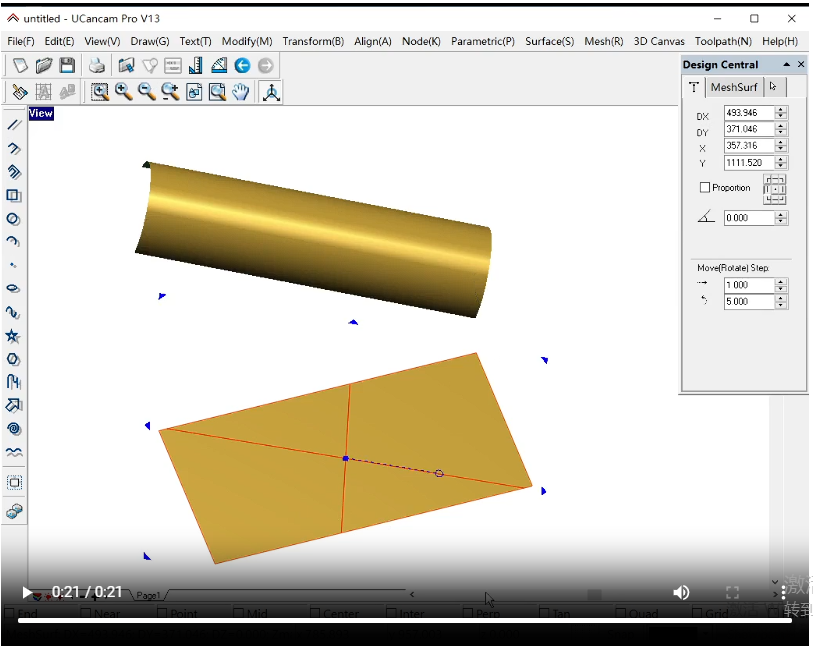

Surface Flattern | |

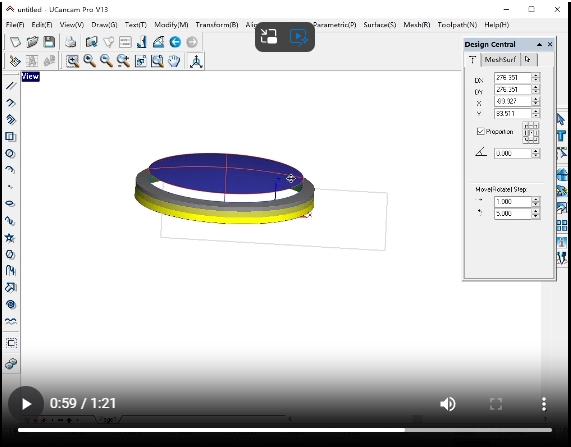

| Mesh Wrap | ||

|

Image to Relief

|

|

|

Standard Relief

|

|

|

Chamfer Relief | |

|

Profile Relief | |

|

|

Sweep Relief:1 cross section / 2 cross section | |

|

|

mesh z slice | |

|

|

Sweep Relief:weave option. | |

|

|

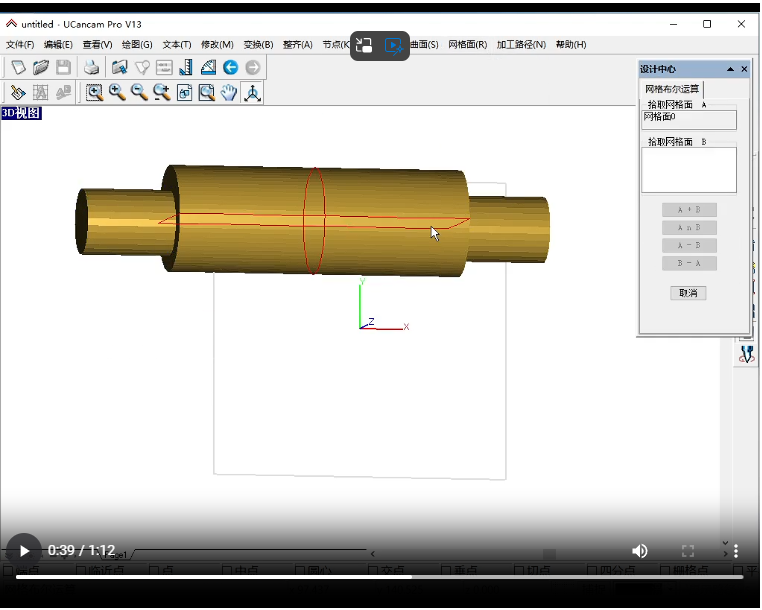

mesh boolean(merge, inetrsectiom ,differrence) | |

|

|

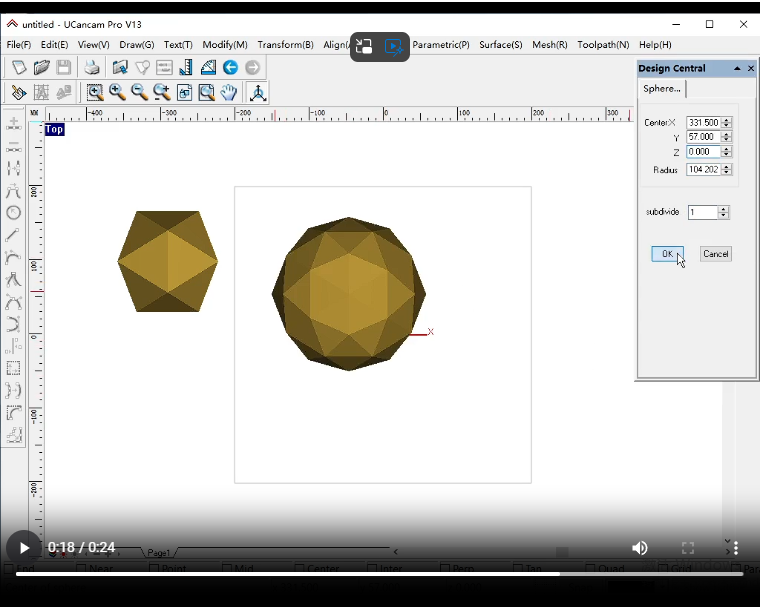

Mesh Primitives: includes Ico Spere; UV Sphere、Cube、Cylinder、Cone | |

|

|

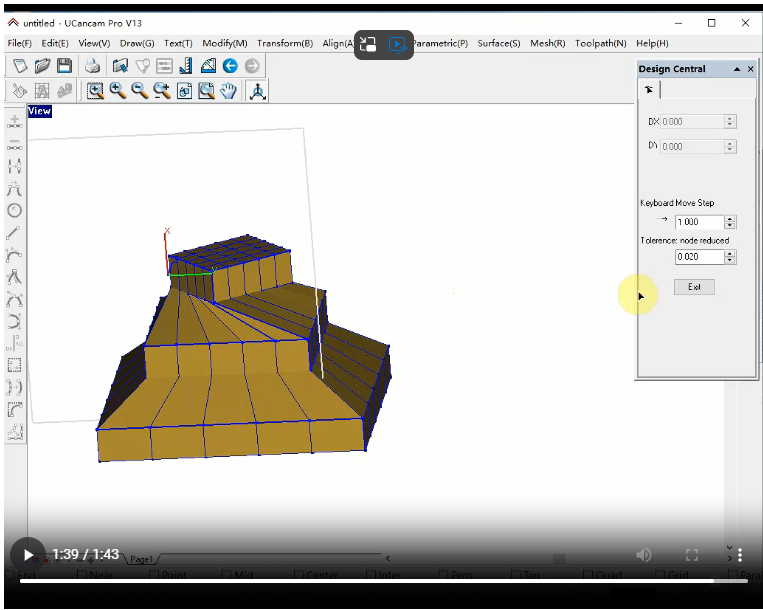

Edit Node of Mesh | |

|

Interactive Nesting After setting the parameters of kerf width, cutting margin compensation and Iteration count; You can automatic nest the parts, and then you can reselect this parts, and manually nest the parts, user-interactive postioning the parts, dragging, rotating and mirroring.this function support drag, drop and bump features. | |

| Relief Sculpt: Brush include:Draw, Clay, Flatten, Inflate,Smooth, Noise, Crease, Pinch,Grab,Trim,Rotate,Move,Reduce,Mask. | ||

|

|

Clay | Flattern |

| Inflate | Smooth | Noise |

| Pinch | Crease | Trim |

| Mask | Grab | Texture Brush Video |

|

Box Mask

|

Line Mask |

Stitch Brush |

|

2.5D Canvase |

||

Relief Add Relief Add

|

Relief Subtract Relief Subtract

|

|

Merge High Merge High

|

Merge Low Merge Low

|

|

、 Replace 、 Replace

|

Demo |

|

| CAM | ||

|

|

Straight Texture Straight texture can be directly generated by selecting different tools and by setting texture sizes , toolpath intervals and undulating lines. |

|

|

Curvilinear Teture Curvilinear texture can be directly generated by selecting different tools and by setting texture sizes, toolpath intervals, sample lines and base lines.

|

|

|

Straight Wave Straight Wave can be directly generated by selecting different tools and by setting texture sizes, toolpath intervals, sample lines, base lines, and wave angles.

|

|

|

Curvilinear Wave Curvilinear Wave can be directly generated ,by selecting different tools and by setting texture sizes,toolpath intervals, wave angles, fold height, sample lines and base lines.

|

|

|

Fan texture Straight Wave | |

|

Fan texture Curve Wave | |

|

|

Texture trimming Designed texts and graphics can be cut out from the generated wave board toolpath .This enables waveboard to integrate with other carving patterns. | |

|

Toolpath Project Machining Toolpath projection onto a complex surface, to complete engraving of text, graphics on surfaces. During projection ,the original relative height can be kept. | |

|

Surface Rough Machining–Parallel Rough machining is for making the general work pieces through rapid removal of excess materials. Rough machining tries to achieve the maximum cutting efficiency while considering the actual situation like blank shape, workpiece shape, machining materials, machining conditions. During the machining, Rough milling can be layered, support equal cutting technology and control machining allowance. | |

|

Surface Rough Machining–Plunge Rough Plunge create drilling-type tool motions for the fast removal of high volumes of material. This procedure is an economical way of deep machining cores, cavities, high shoulder slots and straight or sloped walls.This is a High Efficiency Cutting (HEC) procedure. Plunge mills transfer cutting forces axially, minimizing vibration and deflection. | |

|

Surface Finish Machining–Parallel Surface Milling often makes finish parallel machining with Ball Nose. Parallel machining means the toolpath is parallel.Toolpath machines the entire surface through parallels. The linear cutting machining can be done in any direction or of any angles, but all the surface machining toolpaths must be parallel. In most cases, parallel toolpaths can cut out the best surface. | |

|

Surface Finish Machining–Contour Finish Contour machining can promote the machining speed in the same horizontal plane with Z-axis invariable. Besides, partial contour can also be carried out via limiting the machining range and depth. Toolpath is fitted into arc which reduces the G-codes and improves machining efficiency. This is mainly used for high-speed milling machines. | |

|

Surface Finish Machining–Emit | |

|

Machining Simulation Machining Simulation of milling process can be a true representation. Material texture can be set. | |