Adaptive Area Clearance

What is Adaptive Milling?

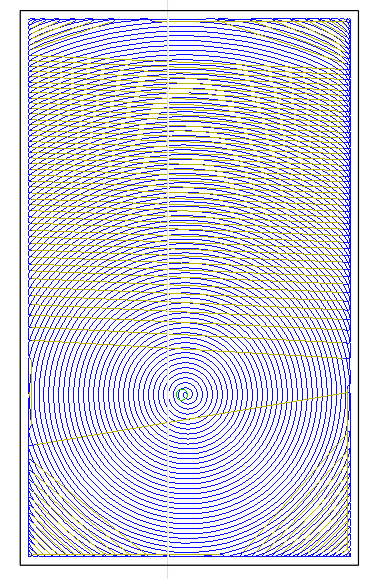

It is an innovative roughing method, which enables deep cuts and consistent tool load, resulting in high material removal rates. Adaptive milling provides higher productivity and longer tool life as it uses stabilized cutting process. This method ensures consistent and evenly distributed stock on tapered and contoured walls. Hence, it is especially useful on Mold inserts.

What are the benefits of using Adaptive Milling?

- Reduces heat generation

- Reduces vibration in the cutting zone

- Reduces the wear of the cutting tools, extending tool life by 4X

- Reduces machining time by 60% resulting in increased productivity

- Smooth cut patterns optimized for high speed machining

- High Speed Machining (HSM) cutting strategies with smooth flowing toolpath for steep and non-steep regions.

What are different types of Adaptive Milling?

- High Feed rate Cutting (HFC) – Small depth of cut, but big stepover, high cutting feed rates

- High Dynamic Cutting (HDC) – Utilizing the complete flute length, but maintaining a consistent chip thickness and high cutting speeds

- High Speed Cutting (HSC) – Small cut depth, but high cutting speeds

- High Performance Cutting (HPC) – Utilizing the complete flute length and a big stepover, while driving with higher cutting speeds than in conventional roughing paths

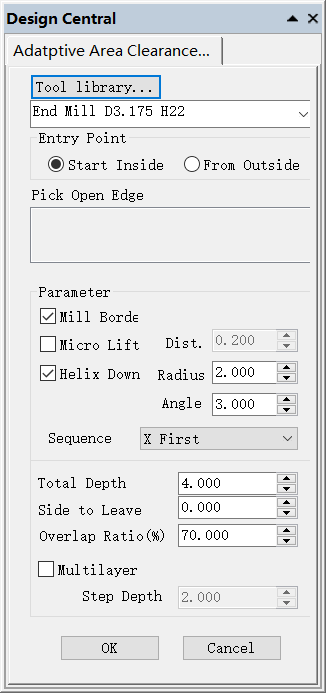

Method of implementation:

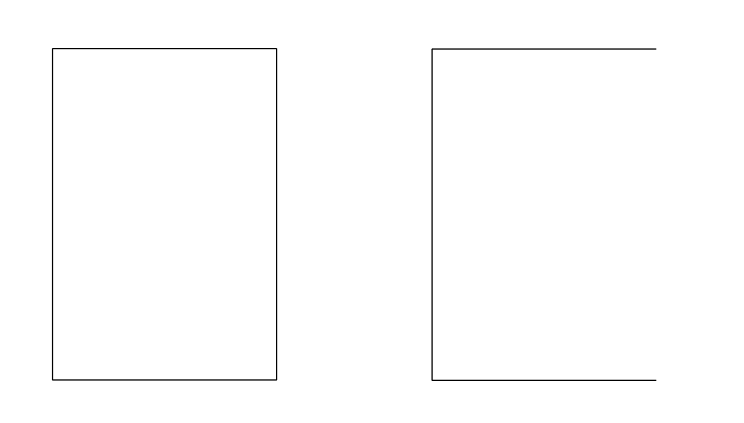

1. select the object.

the object can be closed or open. As the follow:

2. select the menu 【Toollpath> Adaptive Area Clearance】.

3. Select the tool,Entry point,,set the parameters.

4.Pick the open edge(option)。

5. Click “OK”,to create the toolpath.

Parametric Meaning:

1. Entry Point:

Start Inside :

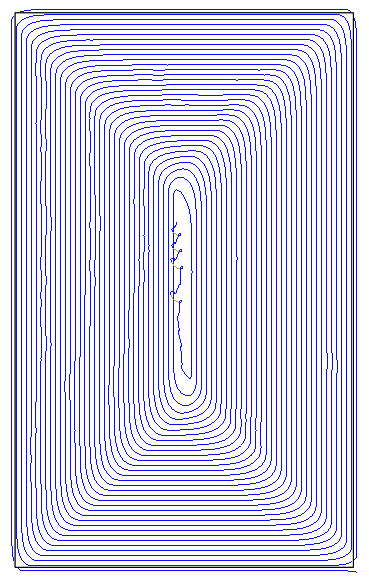

By selecting the Start inside strategy, Dynamic Mill becomes a pocket toolpath that

utilizes dynamic motion. You select a boundary, areas to avoid, and set tooling, param-

eters,. Material is removed from the inside to the outside in a highly efficient manner.

From outside:

By selecting the From outside strategy, Dynamic Mill becomes a facing operation that

has island avoidance capabilities. This movement creates a toolpath that is allowed to

move outside the selected material and removes from the outside to the inside.

2. Pick the open edge: click the list window , pick the region edge.

3. Mill border:This is to make the surface of the material smooth after being machined

4.Micro lift:

Micro lift options allow the tool to rise above the floor of the part for the portion of the toolpath that is not removing material. Benefits of the micro lift include chip clearing and avoiding excess tool heat.

5. Helix Entry:

to enter the material for a adaptive mill toolpath.

Radius:not be great with Tool radius.

Angle:

the following parameters:

6.Sequence:

7.Total Depth:

8.Side to Leave :

9.Overlap Ratio:.

10.Mutilayer:

Refer to:Area Clearance-北京文泰铭心科技有限公司 (ucancam.com)