Tip: Start typing in the input box for immediate search results.

-

Feature

-

Interface

-

File Operation

-

Design Central

-

Basic Setting

-

Viewing Tools

-

Object Operation

-

Drawing

-

Parametric

-

Graph Editing

-

Graph Transform

- Move

- rotate

- Transform Again

- Mirror

- Arc and Line Fit

- Envelop Distortion

- Perspective Distortion

- Push and Pull Distortion

- Twist Distortion

- Shadow Distortion

- Curve Zmap

- Auto Nesting

- Interactive Nesting

- Clone Along a Curve

- Rectangular Clone&Polar Clone

- Clone along a Line

- Clone along an Arc

- Clone along a Spiral

- Scale 2 Points

- Orient 2 lines

- 3D Move

- 3D Rotate

- 3D Scale

- 3D To XY Plane

-

Image Processing

-

Text Editing

-

Node Editing

-

Graph Toolpath

- Tool Path

- Profile Machining

- Area Clearance

- Flute Machining

- 3D Corner Engraving

- Midine Machining

- Drilling

- Insert And Inlay

- Intelligent Machining

- Prism Machining

- Embossing Machining

- Toolpath output

- Tool Management

- Toolpath Walk Simulation

- Toolpath Shaded Simulation

- Post Set

- Toolpath Regenerate

- Toolpath Stat

- Chamfer Machining

- Adaptive Area Clearance

-

Image Toolpath

-

Wireframe Toolpath

-

Toolpath Edit

-

Waveboard

-

Mesh

-

Relief Sculpt

-

Surface

- Surface

- Import Surface File

- Standard Surface

- Freeform Surface

- Chamfer Surface

- Fillet Surface

- Extend Surface

- Show Effect

- To 3D Curve

- Curve Project to Surface

- Pullback

- Extract Edge

- Split at Isocurve

- Trim at Curve

- Trim at Surface

- Untrim

- To Mesh

- Edit Node of Surface

- Insert Control Point

- Vari Fillet Surfaces

- 3D-Spline

- Surface Flatten

- Mesh Wrap

-

Canvas 3D

-

Surface Toolpath

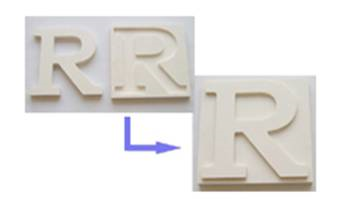

Insert And Inlay

Inserted and inlayed moulds are made by profile machining and area clearance.

Command:

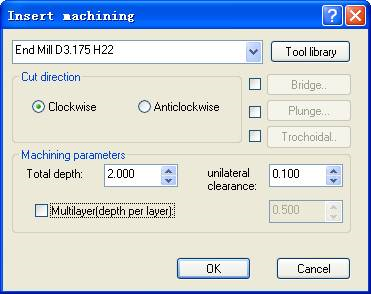

Menu【Toolpath > Insert and Inlay >Insert Machining】 Toolpath Bar

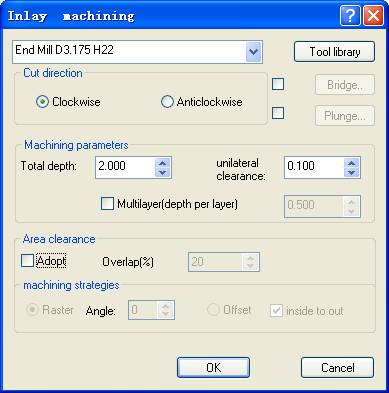

MenuToolpath > Insert and Inlay > Inlay Machining Toolpath Bar

Steps:

1. Select the objects.

2. Click Menu【Toolpath > Insert and Inlay >Insert Machining】.

3. Set the parameters, Click OK button.

4. Click Menu【Toolpath > Insert and Inlay > Inlay Machining】.

5. Set the parameters, Click OK button.

Parameters: please refer to the Profile Machining and Area Clearance.

Unilateral clearance: the distance between the inlayed mould and the inserted mould, This parameter is given in both Inlay and Insert, and you need only input one value.