-

Feature

-

Interface

-

File Operation

-

Design Central

-

Basic Setting

-

Viewing Tools

-

Object Operation

-

Drawing

-

Parametric

-

Graph Editing

-

Graph Transform

- Move

- rotate

- Transform Again

- Mirror

- Arc and Line Fit

- Envelop Distortion

- Perspective Distortion

- Push and Pull Distortion

- Twist Distortion

- Shadow Distortion

- Curve Zmap

- Interactive Nesting

- Auto Nesting

- Clone Along a Curve

- Rectangular Clone&Polar Clone

- Clone along a Line

- Clone along an Arc

- Clone along a Spiral

- Scale 2 Points

- Orient 2 lines

- 3D Move

- 3D Rotate

- 3D Scale

- 3D To XY Plane

-

Image Processing

-

Text Editing

-

Node Editing

-

Graph Toolpath

- Tool Path

- Profile Machining

- Area Clearance

- Flute Machining

- 3D Corner Engraving

- Midine Machining

- Drilling

- Insert And Inlay

- Intelligent Machining

- Prism Machining

- Embossing Machining

- Toolpath output

- Tool Management

- Toolpath Walk Simulation

- Toolpath Shaded Simulation

- Post Set

- Toolpath Regenerate

- Toolpath Stat

- Adaptive Area Clearance

- Chamfer Machining

-

Image Toolpath

-

Wireframe Toolpath

-

Toolpath Edit

-

Waveboard

-

Relief

-

Surface

-

Surface Toolpath

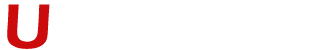

Prism Machining

By prism machining, it becomes easier for you to make characters with prism effect, and sign mark.

Command:

Menu【ToolPath >Prism machining】 Toolpath Bar

Steps:

1. Select the object

2. Click Menu【ToolPath > Prism machining】.

3. Set the parameters, Click OK button.

Parameters:

1)Tool: This Prism machining effect is only gotten by using the conical tool. Thus, only conical tools are provided in the tool library.

2)Parameters: You can set the material thickness and machining depth in this section.

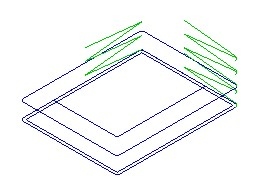

If the machining depth less than prompt, the effect in Figure

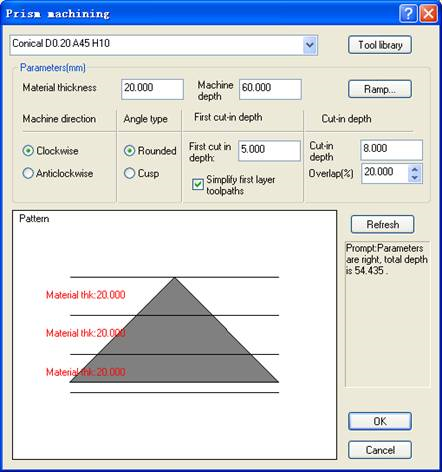

3)Machine direction: is the direction of the toolpath, including clockwise and anti-clockwise. When choosing cutting direction, the material should be taken into consideration so that the surface of the material after being machined is smooth. Clockwise machining is fit for cutting materials of high density, such as Acryl (organic glass), brass, etc; anti-clockwise machining is fit for cutting materials of low density such as PVC board, two-color board, etc.

clockwise anti-clockwise

4)Angle type: includes rounded and cusp angles.

Cusp rounded

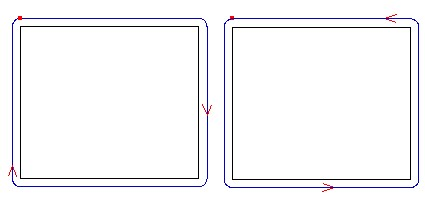

5)First cut in depth: The first layer of the milling depth, As milling capacity, so the depth should not be too deep, can not exceed the cutter height.

Simply first layer toolpaths: Cancel the external path of the first layer.

Simplify before Simplify after

6)Cut in depth:After the first layer milling, per layer depth in remaining processing(Can be used instead of overlap).

7)Preview window: Prism section created is previewed in this window.

Refresh: if the Prism section created did not show in preview window, click refresh button.

Prompt: It automatically prompts you whether you have chosen a proper tool, and lets you know if the cutting depth is right or not.